A low cost route for marine hydrogen

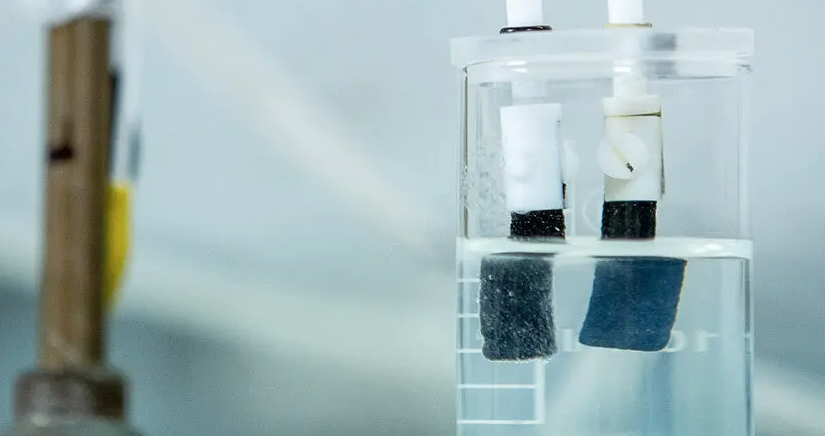

(sustainabilityenvironment.com) – Increase the volume of studies and research dedicated to marine hydrogen. In recent years, the idea of being able to directly generate the carrier from salt or dirty water to preserve fresh and potable water sources has continued to make its way into the scientific world. Among the latest advances in this regard is the work done at RMIT University in Melbourne. Here a team of engineers, in collaboration with materials experts and Australian Synchrotron, has improved electrolysis to be able to generate green hydrogen from seas and oceans simply and economically.

One of the biggest problems of marine hydrogen is the co-production of chlorine, as Doctor Nasir Mahmood explains, among the authors of the research. “If we were to meet the global demand for hydrogen without solving this problem first, we would produce 240 million tons of chlorine every year […] It makes no sense to replace hydrogen produced from fossil fuels with hydrogen production that could damage our environment differently“. But it’s not the only problem. Electrolysis at sea also needs valuable catalysts and high amounts of water: about nine liters may be needed to produce just one kilogram of H2.

Nickel and molybdenum sheets for marine electrolysis

To reverse the trend, scientists created a special catalyst that could work specifically with seawater that was also efficient, stable and economical to produce. It also “requires very little energy to operate and could be used at room temperature,” Mahmood explained. “Although other experimental catalysts for splitting seawater have been developed, they are mostly complex and difficult to scale materials“.

Read also From EPFL the artificial leaf that produces hydrogen from the air

The RMIT University recipe used sheets of nickel phosphide molybdenum doped with nitrogen, sprinkled superficially with tiny pores able to accelerate catalytic activity. Tests have shown that the new catalyst is exceptionally efficient, completely suppressing chlorine generation. The next step will be to build a prototype electrolyzer that incorporates a stack of these catalyst sheets, to produce large quantities of marine hydrogen, optimizing the yield on a large scale. The research was published in the journal Small.