Thermal insulation of windows, cellulose aerogel reduces the gap with walls

Is it possible to increase the thermal insulation of windows without compromising transparency and high functions? In 2016 a group of scientists, led by Professor Ivan Smalyukh, started from this question to develop a new approach to improve the energy performance of buildings.

How to reduce heat loss

As a rule, glazing and fixtures is the weak element in terms of heat loss in homes. It is estimated that on average a house loses 25 to 30 percent of its thermal energy through windows. And although there are several solutions and tools, such as double and triple glazing, to increase insulation heat losses remain inevitable.

This is where the research of Smalyukh and colleagues from the University of Colorado Boulder fits in. The group used a new process to create a solid, transparent film that was both highly insulating, soundproof and resistant to water condensation. As explained in the article on Nature Energy, scientists have created a new aerogel printable to be inserted in double glazing instead of air or noble gases commonly used. And they did this by using as raw material a waste: the cellulose discarded by the wood industry.

The power of cellulose aerogel for single or double glazing

Mixtures of a gas and a solid, aerogels are extremely light and thin materials but can offer a thermal resistance equal to that of a traditional insulator. The Colorado University team has developed a production process based on pulp compatible with roll-to-roll printing.

In detail, the researchers immersed cellulose nanofibers extracted from wood in water, obtaining a colloidal dispersion thanks to an oxidative process; by adding acid they transformed the latter into a hydrogel. So they dipped the hydrogel in an ethanol-based solution and heated it in a pressurized furnace, so that the spaces inside the nanofiber network would fill with air. Last step: the material has been coated with a water-repellent substance to prevent condensation of water particles once applied to the glasses.

Thermal insulation and transparency for windows

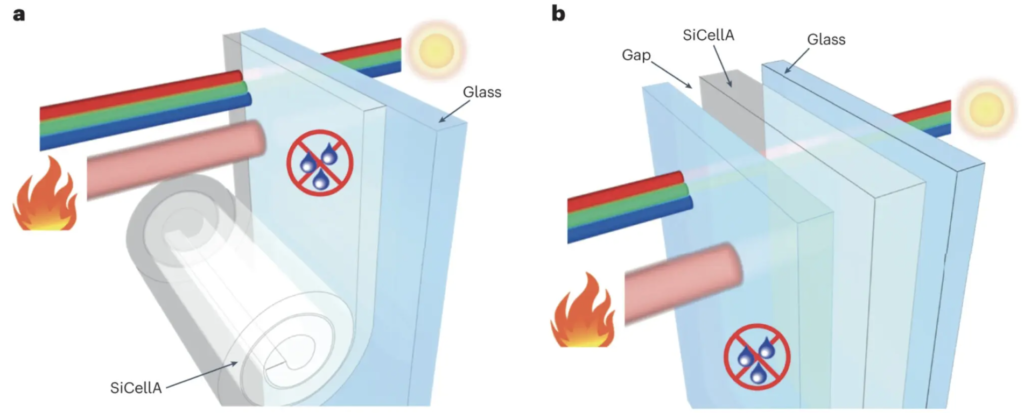

The result is a thin film with the light transmission in the visible field of 97-99% (better than glass), a haze factor of less than 1% and a thermal conductivity lower than that of still air at 20 ºC. The finished product lends itself to increasing the thermal insulation of any window. As explained in the document, a thin film of the new aerogel could enhance the thermal barrier performance of a single glass window when used as a retrofit on its inner surface. Or, once inserted in the insulating glass, allow to increase in the distance between the glasses and increases the thermal performance even more. Tests showed that a gap of 2.5 centimeters provided the same degree of insulation as an insulated wall.