Hydrogen Liquefaction, how to make it less expensive

(sustainabilityenvironment.com) – One of the greatest difficulties in creating a global green hydrogen trade lies in the carrier’s long-distance ocean transportation. While waiting for the chemical storage of H2 through third substances or materials, at the moment the most practical solution at the technological level is to make it liquid, as is done with natural gas. The problem is that hydrogen liquefaction is an expensive process that requires cryogenic temperatures (20 Kelvin, -253°C), creating many obstacles to supply chains. It is estimated that the current installations for the production of liquid hydrogen need about 13 kWh of electricity per kg of hydrogen.

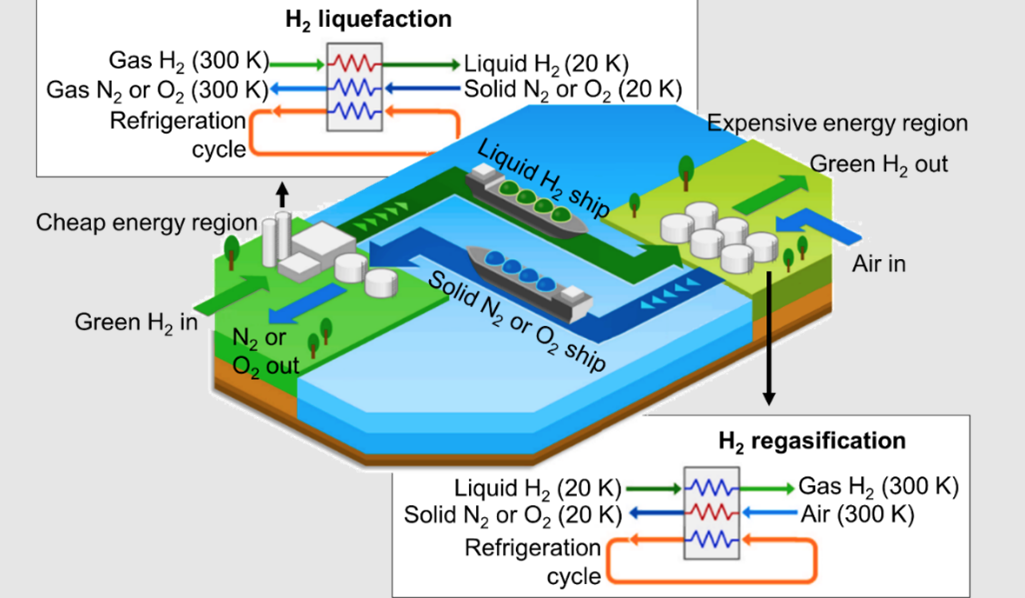

A group of researchers from the Institute for Applied Systems Analysis (IIASA) in Austria have studied an approach to make everything cheaper. How? Coupling in the supply chain the liquefaction of the H2 to the solidification of the air. In detail, the team studied the possibility of using nitrogen or solid oxygen as a means to recycle cooling energy during regasification of the liquid carrier.

The Solid Air Hydrogen Liquefaction

The Solid Air Hydrogen Liquefaction, this is the name of the process, is divided into four main phases: regasification of hydrogen, transport of N2 or O2 solids, liquefaction of hydrogen and transport of liquid hydrogen.

read also Natural Enzymes to Produce Green Hydrogen low cost

The first phase involves the extraction of the cooling potential from the liquid H2 to solidify nitrogen and oxygen that will then be sent to the plant where the carrier has been liquefied. Solid air is therefore used to reduce the energy consumption needed to cool gaseous hydrogen. According to the researchers’ study, the energy required to liquefy hydrogen can be reduced by 25.4% using N2 and by 27.3% using O2.

The use of solid air as a means of recycling cooling energy through the hydrogen liquefaction supply chain can reduce costs and energy consumption for carrier transport across continents,” says lead author Julian Hunt, researcher at the Integrated Assessment and Climate Change Research Group of the IIASA Programme for Energy, Climate and Environment. “This would increase the feasibility of a global hydrogen economy in the future and the number of hydrogen suppliers for energy-demanding regions such as China, Europe and Japan”. The research was published in the International Journal of Hydrogen Energy.