Alternatives to plastic: silk protein based biomaterial from MIT

(Sustainabilityenvironment.com) – The race for alternatives to plastic continues: in this case, a group of scientists from MIT and the chemical company BASF, located between Germany and the USA, studied the effectiveness of silk as a substitute for plastics used for the preservation of a series of products. The work was conducted by MIT researcher Muchun Liu, the professor of civil and environmental engineering of the institute Benedetto Marelli, and five other scholars at the chemical company BASF in Germany and the United States.

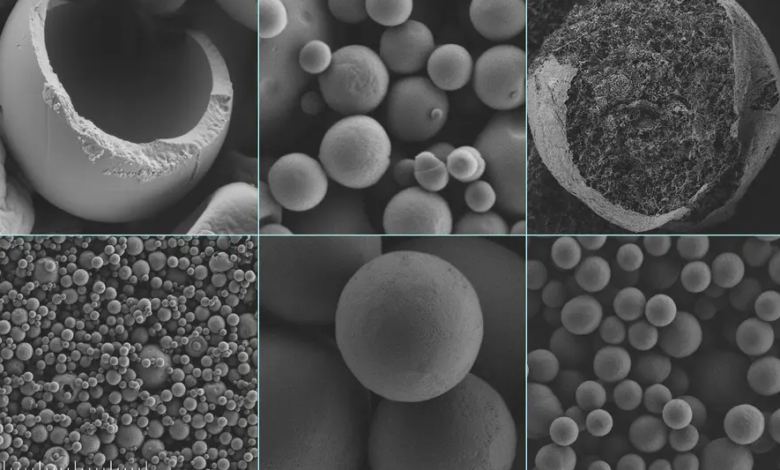

Plastic is currently used to protect the active ingredients of certain products that could be degraded by air or moisture. An example? Vitamins, often released as pills or capsules, pesticides and herbicides. The problem is that the plastic used for these forms of self-encapsulation persists for a long time in the environment.

However, the team of scientists has identified silk as a valuable substitute. Not really in the fine fabrics that we are used to imagining, but in an alternative material that can be made from the proteins that make up its fibers in a simple and economical way.

In order to produce the tissues, a slow and painstaking process is needed, which requires that the cocoons of the worms are unrolled to obtain thin threads. For this material, however, you can use non-textile cocoons or dissolve silk fibers directly in water. This method can also use low-quality silk, which would be discarded from the production of fabrics, introducing elements of circularity in the life cycle of a product that typically ends up in landfills.

Read also The study that will show the real extent of microplastic pollution

This process is so simple that it can be adapted to existing equipment. In laboratory tests, researchers demonstrated how silk-based coating material can be used in the industrial production of microencapsulated and water-soluble herbicides.

The capsules were tested in a greenhouse on a corn crop, proving they could work better than the products already on the market. The fact of not being bound to high-quality fibers also has additional benefits: 90% of world silk production takes place today in China, especially because the country has perfected the production of high-quality threads for the manufacture of fabrics. Not needing this particular skill for this use, however, production could be widespread in many other parts of the world and generate a situation of territorial response to local demand. The work was published in Small magazine.