Aluminium sodium batteries, towards high energy density

The low cost option of sodium aluminum batteries

(sustainabilityenvironment.com) – The new aluminium sodium batteries designed for stationary storage come from the Pacific Northwest National Laboratory (PNNL), one of the key laboratories of the US Department of Energy. The underlying technology is that of molten salts with which today rechargeable devices are made at high operating temperature (between 245 and 350 ºC), to be used for the network or large industries. But the PNNL approach has revisited the architecture almost completely, making progress on both performance and cost. “We have shown that this new fused salt battery design has the potential to charge and discharge much faster than other [thermal] sodium batteries, operating at a lower temperature and maintaining excellent storage capacity“, said Guosheng Li, a PNNL materials scientist and first author of the research.

Currently there are three large types of rechargeable using molten salts: sodium-sulfur, ZEBRA sodium-nickel and those with liquid metal. For each of these devices there are several advantages but the high temperatures, linked to the melting points of electrolytes, complicate their operational applicability.

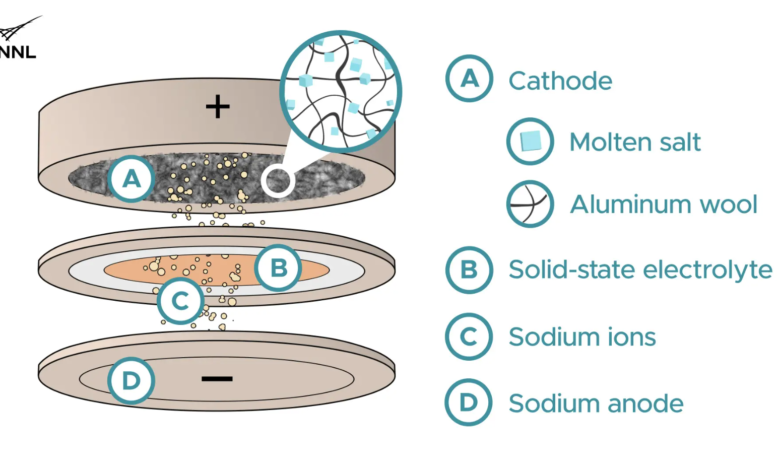

The new design developed by PNNL researchers offers a promising alternative. The team employed a sodium anode and a cathode consisting of alumin wool and a salt (sodium tetrachloraluminate) separated by a solid-state electrolyte, also sodium-based. To the traditional tubular shape, the group preferred a flat configuration that can be more easily stacked and scaled. This specific architecture allows you to increase the capacity of the cell simply by using a thicker cathode.

The result? The new sodium aluminium batteries supported a sustained discharge of 28.2 hours under laboratory conditions showing a specific energy of about 119 Wh/kg and lower temperatures than the rechargeable fused salt batteries on the market today. “Significantly increasing the cathode thickness – read the research published on Energy Storage Materials – results in a discharge duration of 28.2 hours with an estimated cost of active raw materials of 7.02 dollars per kWh”.