Ansaldo’s gas turbine can burn 100% hydrogen

The first successes of the European project FLEX4H2

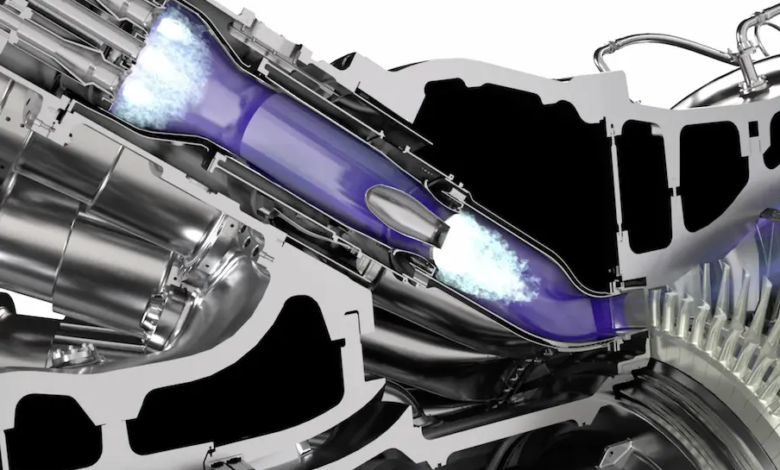

– The project “FLEX4H2” has made it. The GT34, Ansaldo Energia’s first-class H gas turbine, can only operate by burning hydrogen. An announced success whose merit goes to the new design of the combustor and to the commitment of the eight partners who launched the initiative in January 2023.

Flexibility for Hydrogen, the full name of the project, was created to support the ambitious European climate goals by developing a combustion system flexible in terms of fuel and operation. In detail, the consortium, led by Ansaldo itself, has given itself 4 years to design, develop and validate a system that is safe, efficient and able to work with any concentration of hydrogen in the mixture. Up to 100% H2. A goal pursued in the most demanding combustion conditions, that is at operating temperatures of class H, required for maximum cycle efficiency. All but respecting rigorous limits of emission without the use of diluents.

Ansaldo Gas Turbine switches to pure hydrogen

The new design is based on Ansaldo Energia’s Constant Pressure Sequential Combustion (CPSC) technology, which uses two systems: one with aerodynamic flame stabilization and the other stabilized by self-ignition. All work has been and will continue to be supported by multiphysics simulation.

“The decarbonisation of gas turbines is a fundamental part in the transition of the energy landscape”, said Federico Bonzani, Product and Technology Director of Ansaldo Energia at the launch of the project. “A single engine, equipped with the new FLEX4H2 combustion system, has the potential to eliminate up to 2,000,000 tons of CO2 emissions per year, while providing sufficient clean energy to supply up to 500,000 households”. And even though only a year has passed, the partners have already made great progress.

The tests of the prototypes of the new combustor carried out in a test plant in Germany proved the goodness of the initial intuitions. Allowing Ansaldo’s gas turbine to work with pure hydrogen. The tests showed the combustor’s ability to switch continuously from natural gas to H2, with extreme operational flexibility. “The innovative sequential combustion technology allows the GT36 to use a wide range of mixtures of hydrogen and natural gas, ensuring its adaptability to the evolving needs of the current and future power generation markets”, writes the company on its site.