Electrolysis cells Ni-GDC for the future power-to-X

It will take up to 10 years before Ni-GDC electrolysis cells are scaled

“If we could get the ceramic electrolysis cells into the power-to-x technology at enough sites around the world, their efficiency could save 25% of all the electricity needed to produce the same amount of green fuel and save up to about 20% of the price of hydrogen“. With these words, Henrik Lund Frandsen, professor of the Department of Electrochemical Energy Conversion and Storage at the Technical University of Denmark (DTU) describes the innovation developed by researcher Morten Phan Klitkou and colleagues.

In the laboratories of the Danish university, electrolysis technologies have long been at the center of a dense activity of research and industrial collaboration. Last year, Topsoe started the construction of the world’s first large-scale factory for the production of high-temperature electrolysis cells, making use of the progress made together with DTU Energy.

Ni-GDC electrolysis cells, the evolution of SOEC?

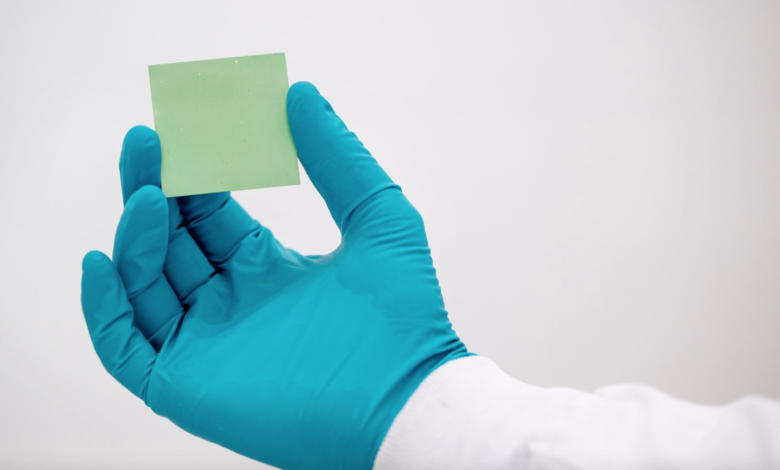

Today the university relaunches with another very promising research. Scientists have in fact manufactured and tested a new type of solid oxide electrolysis cells (SOEC) with Ni-GDC cathode, which is based on nickel and ceria doped with gadolinium.

Generally SOEC cells possess as cathode material (also called Fuel Electrode) zirconia stabilized with yttrium (YSZ) and doped with nickel, the catalyst. But at high current densities this compound undergoes nickel oxidation, which causes the degradation of catalytic activity. The electrodes in Ni-GDC show greater stability. The tests, performed at different currents for 1,000 hours, showed that it can withstand practically (almost) no damage. A slight degradation occurred only in case of very high current consumption.

“Experiments have shown that the primary degradation mechanism of conventional ceramic electrolysis cells could be avoided since nickel in the electrode remains stable even under high current absorption. Current technology would never have been able to tolerate it,” writes Peter Aagaard Brixen on the university’s website.

Obviously not everything is perfect. The researchers found that there are still some technical nodes to dissolve since the new Ni-GDC electrolysis cells cause problems at the electrolyte level. Despite this, they believe the results are very promising for future power-to-x (ptx) processes where green hydrogen production is the necessary step to obtain products such as ammonia, valuable molecules for the chemical industry, new fuels and even food.