Bricks from waste materials can make building sustainable

Cooking oil, sulphur and dicyclopentadiene (DCPD) for new bricks from waste materials

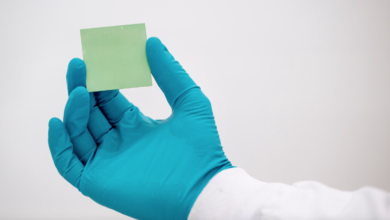

(Sustainabilityenvironment.com) – Building bricks from waste materials will pave the way for more sustainable building: researchers at the Flinders Chalker Lab in Australia are convinced of this. The group of organic chemists is looking for less expensive alternatives with less environmental impacts than brick firing and the production of mortar and cement, focusing on the use of low-cost raw materials to create construction elements that guarantee the strength of traditional bricks. Their study resulted in the production of bricks from waste materials that are held together thanks to a chemical reaction, without the need for the use of gluing substances.

With bricks from waste materials construction goes towards the circular economy

The lightweight polymer blocks made by the team of scientists are composed of low-cost raw materials, and do not require the use of mortar or other adhesive substances. The study monitored the strength of the waste material used and verified how the bricks produced can be used for construction. According to chemistry professor Justin Chalker, it is crucial right now to reduce the emissions represented by the construction industry: the production of iron, Cement and steel account for 15% of global CO2 emissions and research is required to work to lower these figures.

For this reason he has engaged the activities of his laboratory to the definition of the perfect formula to make bricks from waste materials: “In this study we tested a new type of brick that we can make from kitchen oil waste, mixed with sulfur and dicyclopentadiene (DCPD). Both sulfur and DCPD are by-products of oil refining. Our research is part of a wider effort to move towards a sustainable built environment“.

A search that is just beginning

The Chalker Lab is a facility of the Flinders University College of Science and Engineering. The research team that conducts the activities has collaborated, during the research, with Clean Earth Technologies.

Their results deserved the cover of a special issue dedicated to Sustainability of the magazine Macromolecular Chemistry and Physics: in the insert the team illustrated the latest developments of its study, such as the results of tests on the mechanical properties of bricks and attempts to make them more resistant with carbon fiber fillers.

One of the associate researchers who worked on the project, Maximilian Mann, explained the advantages of gluing the production of bricks from waste materials: the sulfur-sulfur bond allows not to use the mortar: “Bonding in this new catalytic process is very strong, producing a material that can be coated with its own mortar that will potentially simplify construction”.